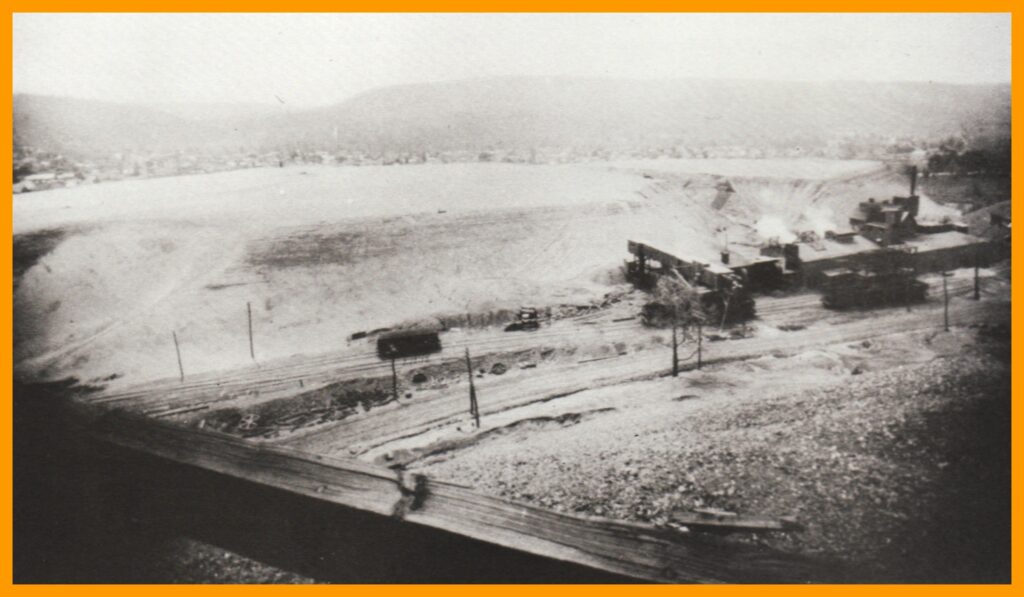

A photograph of the briquet plant from about 1921 or 1922. The plant was located at the western end of Wiconisco, Dauphin County, Pennsylvania. It was built in 1919 and was destroyed by fire in May, 1923.

The following history of the plant was compiled from information in the Souvenir Book for the Wiconisco Sesquicentennial, 1839-1989:

AMERICAN BRIQUET PLANT

The American Briquet Plant was located at the western end of town, on the south side of Pottsville street, opposite the current MEDCO Building [989] in Coaldale. The plant, owned by the American Briquet Company of Philadelphia, and its 75-foot high culm bank, encompassed the entire area from Pottsville Street south to the Wiconisco Creek bed and east to Polish Row.

[Note: Polish Row was an area past Pottsville Street & Market Street intersection, traveling south toward the Market Street Bridge. Many Polish immigrant homes were situated here].

The briquet operation began in November 1919. It employed approximately 75 men and ran three shifts. Working conditions were very difficult due to the extreme heat and unpleasant odor caused by the manufacturing process.

To make the briquets, a binder called a “hite binder” was added to the coal dirt. Composed of a mixture of corn flour, hot and cold water, and asphalt, seven-and-a-half tons were made at one time. The recipe called for 1500 pounds of hot water, 550 pounds of cold water, 187.5 pounds of corn flour, ad a small amount of asphalt.

The operation consisted of a cable attached to the south side of the plant, running to a large A-frame located near the Wiconisco Creek. A bucket large enough to hold 15 tons of coal dirt was attached to the cable on the A-frame. This bucket would scoop up the dirt, travel up the cable to the plant and dump it into a bin. Screening was done to eliminate the larger pieces of coal.

The discarded coal was used to fire the boilers which produced the steam needed for the operation of the plant. The fine coal, or culm, was mixed with the binder and went through several mixing processes until thoroughly combined. The rule of thumb for judging if proper consistency was obtained is as follows: Take a handful of the mixture and squeeze it. If you have a lump that stays together and shows your finger imprint on it, it is correct. If it sticks to your hand, too much binder was used. The pressman was responsible for regulating the amount of ingredients used.

From this point the mixture went into another hopper and was sent to the press. The press involved two large cylinders which, when rolled together, molded the mixture into the briquet shapes. The briquets were dropped onto a conveyer, which traveled very slowly, passing under steam pipes which heated and dried the briquets. This conveyer setup was about 10 feet wide and 100 feet long.

When the baking process was complete, the briquets were loaded onto Pennsylvania Railroad cars. A large quantity of the briquets was shipped to the New England states where they were utilized as fuel instead of coal.

_______________________________________________________

Corrections and additional information should be added as comments to this post.