On November 11, 1949, the West Schuylkill Herald of Tower City published an article on the relatively-new apparel factory, Phillips-Jones Corporation, at Muir, Schuylkill County, Pennsylvania. The article focused more on the history of the company than on its presence in Muir. The main offices were located in Pottsville.

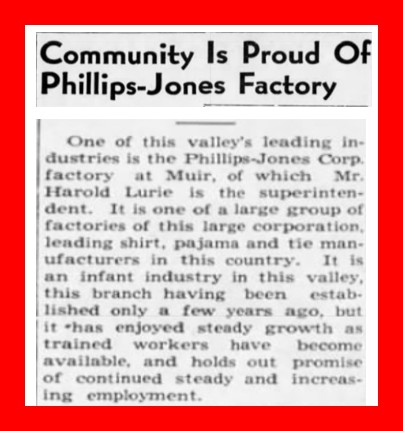

COMMUNITY IS PROUD OF PHILLIPS-JONES FACTORY

One of this valley’s leading industries is the Phillips-Jones Corporation factory at Muir, of which Mr. Harold Lurie is the superintendent. It is one of a large group of factories of this large corporation, leading shirt, pajama and tie manufacturers in this country. It is an infant industry in this valley, this branch having been established only a few years ago, but it has enjoyed steady growth as trained workers have become available, and holds out promise of continued steady and increasing employment.

The article then proceeded by quoting facts which were published in the Pottsville Journal:

Four years after entering business, or in 1920, the Phillips Shirt Company showed the first definite signs of expansion with its removal from the Mountain City Building to the present, but much smaller building on Mauch Chunk Street. This expansion continued throughout the years, with the Phillips-Jones Corporation presently operating factories not only in the Pottsville area, but at Patton, Kane, and Barnesboro in Pennsylvania, and in Alabama, New York, and Rhode Island. Twenty-five hundred Pennsylvanians are employed in P-J plants which have an annual payroll in excess of $4,000,000, to say nothing of large sums paid for raw materials, transportation and other items in conjunction with the operation of a business that weekly turns out approximately 16,000 dozen shirts, of which 4,300 dozen are produced locally, plus sports shirts and pajamas.

Salesman Originated New Idea

Not only is the Phillips-Jones Corporation one of the nation’s largest manufacturers of shirts, but its inception of the famed Van Heusen shirt – the trade name of the P-J product, revolutionized the industry early in the 1920s. At this time, the starched collar was entirely the vogue since no technique had been devised for making a soft collar that would retain its shape when moistened by perspiration, and thereby hangs a tale that is a saga of the romance of the shirt industry.

As the story goes, a salesman named John M. Van Heusen entered his Philadelphia hotel room at the conclusion of a hot summer’s day during which he had changed shirts three times because of the wilted condition the perspiration soaked collars. As he removed his shoes he noticed the canvas-like shoe lining did not seem to be affected by moisture, This set him to thinking, “Why can’t a shirt collar be made that will withstand moisture and not lose its shape?”

Van Heusen thereupon began to experiment and soon came up with the idea for a shirt collar. This consisted of weaving a multi-ply fabric from fine cotton yarns and included a natural fold-over for the collars. The idea was offered to a number of shirt manufacturers but rejected as impractical and expensive. Van Heusen offered the idea to Phillips-Jones, which firm declined to purchase it outright but offered to purchase it outright but offered to experiment with it on a royalty basis. Instantly the collar became a big success and sales soared. royalty payments to Van Heusen the first year exceeded the amount originally requested as the purchase price.

A few months ago Phillips-Jones introduced a new improved type collar known as the Century, which cannot wrinkle. This is proving just as revolutionary in the shirt industry as was the introduction of the P-J Collarite shirt over the early day soft collar. Some nylon shirts are also being produced.

From the few hundred dozen shirts produced weekly when the Phillips firm first entered the shirt making business, the production of P-J factories reached an all-time high during World War II when five and one-half million shirts were manufactured for the U. S. Army. This production was equal to one shirt every second and a half during the time the P-J factories were in operation during the war period, or approximately 18,000 shirts per eight hour shift.

Not only has production expanded during the last half century since the Phillips family entered the shirt business, but so has the physical appearance of the local factory. The original 5 by 120 foot building fronting on Mauch Chunk street now measures 88 by 120 feet, with additional buildings almost covering “Furnace Island” to the rear, once the site of an iron ore furnace and canal boat docks. The total floor space in the local plant aggregates 170,000 square feet.

The 100 employees who worked in the first Pottsville plant in the old Mountain City Building in 1898 grew to 300 by 1921 and now numbers between 950 and 1000 in the Pottsville plant.

The present name of Philips-Jones was acquired when the Phillips interests merged with D. Jones and Son, operators of a Lebanon County chain of factories to form the Phillips-Jones Corporation. In 1910, W. J. Biever came to Pottsville from Lebanon County as local manager, retaining this position until his retirement in August 1942 when he was vice president in charge of production.

Other expansions by the P-J firm came in 1920 when it took over the operation of the Koons Garment Factory at Minersville where shirts are presently manufactured. In 1924 when it acquired a Coaldale factory, where sports shirts are presently manufactured, and in 1945 when it took over a former stocking mill at Muir, for the manufacture of pajamas. Other firm plants included in the expansion are: Barnesboro, Patton and Kane, Pennsylvania; Hartford and Geneva, Alabama; and neckware and bleaching plants in Bronx, New York, and two weaving miles in Rhode Island.

Seymore J. Phillips, son of I. L. Phillips, the first president of the P-J firm, is the present head of the corporation and a staunch advocate of the policies laid down by his father and grandfather to make Pottsville the capital of the shirt making industry. Toward this end the Pottsville plant is the shipping point for all firm factories, and all shirts and pajamas manufactured in the other factories are returned there for packing and shipping. Incoming and outgoing freight at the plant approximates six freight carloads daily. And since all paper boxes used by the firm are manufactured by the Pottsville Box Company an additional number of people are indirectly given employment by the presence of the shirt factory there.

See also:

News article from Newspapers.com.

Corrections and additional information should be added as comments to this post.