A portrait photograph of Charles F. Nelson followed by an April 1941 photo essay on the production of a Canada Dry beverage at the new bottling plant of Charles F. Nelson at Reinerton, Schuylkill County, Pennsylvania. The photos appeared in the West Schuylkill Herald of Tower City, April 18, 1941, along with an article titled “C. F. Nelson Opens Large New Bottling Plant at Reinerton For New Canada Dry Cola Drink ‘Spur.'”

This valley’s newest industry, a large new bottling plant for the manufacture of “Spur,” a Canada Dry drink of recent origin, was formally opened last week, and is now in full-time production. Mr. Charles F. Nelson, local ice manufacturer, beverage distributor and wholesale feed dealer, is the owner of the new plant and is the licensed bottler and distributor of the popular drink in Schuylkill, Northumberland and Snyder Counties.

The building which houses the bottling plant is a new one 40 feet by 52 feet, two stories high, and is constructed of concrete block and steel throughout. It is located just east of the large ice manufacturing building of Mr. Nelson, of Reinerton, along state highway 209.

The plant is said to be one of the finest, most sanitary and best constructed for its particular purpose to be found in the state. As one visitor to the plant remarked, “I have seen many larger bottling plants, but never one so modernly equipped, so sanitary, and so conveniently arranged.” One must visit the establishment and see it in operation to appreciate the truth of that statement.

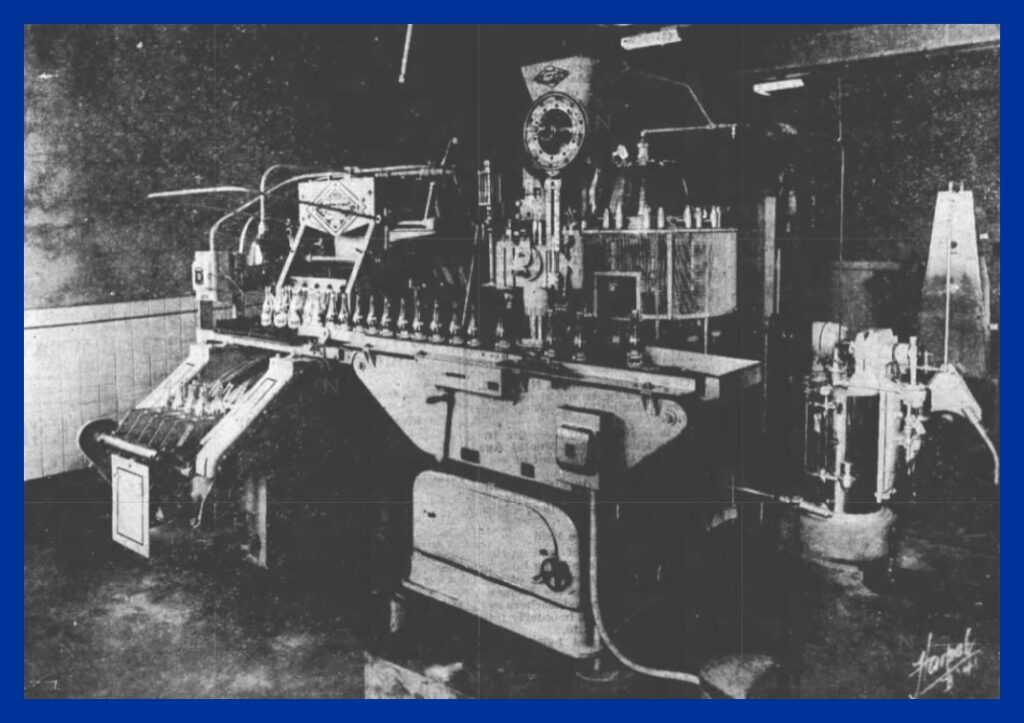

The first floor contains the bottling equipment and storage room. A one-story annex contains the large tubular steel boiler used in heating the building, water and in furnishing steam for sterilizing purposes. The bottling equipment is a massive unit that occupies almost half the floor space in the room. Everything is done automatically by the machinery, from the time the used bottles are placed into it until the filled and capped bottles emerge from it.

Empty bottles require about 20 minutes to go through the cleaning and sterilizing machine. Here they are subjected to a number of washings both inside and outside, and are immersed in boiling water for ten minutes. Brushes whirling at high speed and spraying water are forced through the bottle openings, assuring thorough cleansing, When the bottle come from this unit, ready for filling, they are thoroughly cleaned, sterilized and dries, and sparkle in their brightness.

A conveyor line takes the bottles and carries them to the filling unit there the syrup and other ingredients are automatically forced into the bottles without spilling a drop on the outside, and the caps clamped on. The machine at normal speed bottles 24 a minute.

Several sizes are made, but the most popular is the 12-ounce size which sells for 5 cents retail, giving two full classes for this small price. In addition, the Spur cases contain 28 bottles, which is also an advantage given by Mr. Nelson to his customers.

Adjoining the bottling room is the large storge room where 2500 cases of Spur are kept on hand to meet ordinary requirements and any unusual demands, and assures the dealers a supply at all time.

The second floor of the building contains the offices, display room, garage, sugar and other supplies storage rooms, and the mixing laboratory. The mixing laboratory is a room that would delight the most critical housewife or laboratory worker in its appointments and bright cleanliness. High tiled walls and floors here, as well as the bottling room, with large windows that give plenty of daylight, brighten the interior. White enameled fixtures and chromium plated tanks with their electrical mixer give added brightness in the room. he is found all necessary testing and laboratory equipment. An operator, trained in the New York office of the Canada Dry Company, tens the mixing and testing laboratory. but to insure a perfect drink to the customers, samples of each mixture are sent every day to the testing laboratories off the Canada Dry Company in New York. That is one of the requirements under which Mr. Nelson operates as a licensee of that company.

In an ordinary day’s run, the establishment uses about one-half ton of sugar, besides the other ingredients that go into the product. The offices are being finished in knotty pine in natural color, and here all the business of Mr. Nelson’s ice plant, beer and feed business, as well as the bottling plant, will be conducted in the future.

One room in the building is devoted to a display of the various types of advertising material that are supplied by the Canada Dry Company and Mr. Nelson to the merchants and distributors handling this product.

All water used in the plant is secured from deep wells sunk on the land of Mr. Nelson near the bottling plant. The water is tested frequently by the State Health Department and meets every requirement.

A fleet of trucks keeps the sub-dealers supplied at all times. Mr. Nelson supplies the retail trade in his immediate territory with one large new truck especially built for him at Elizabethville, and which is beautifully colored and illustrated with the Spur advertising. Similar trucks are used by the distributors in St. Clair and in Sunbury.

Visitors are welcome at the Spur bottling plant at all times and will be cheerfully shown through the building.

In these three 100-gallon chromium plated tanks are mixed the ingredients required for the manufacture of Spur. The room is as sanitary as it is possible to make it. In the mixing room there is a laboratory with necessary test tubes, weighing devices, thermometers and other instruments required to make the exacting mixture use in the manufacture of Spur. From these tanks the syrup is pumped to the bottling room directly below. About 650 pounds of sugar is required in an eight-hour day, and it is expected that when production and distribution reach the peak summer point a ton of sugar will be used daily.

__________________________________________________

This is a view of the large storage room where more than 2500 cases are kept on hand at all times to meet the demand of distributors and stores which handle the product. Each large case contains 28 bottles of 12-ounce capacity. There is also a quart size for family use, with 12 bottles to the case.

________________________________________________________

This illustrated the bottling equipment of the SPUR plant. Used bottles are placed in the machine at the lower hand corner of the unit. They are carried by a conveyor line to the washing machine and scalding and sterilizing cabinets About twenty-five minutes is required for the washing and sterilizing of the bottles. The clean bottles, ready for filling, emerge from the machine onto a conveyor line, just above the place where they entered. This line carries the bottles to the filling apparatus, where the proper mixtures are automatically placed in them and they are capped. From the time the used bottles are placed in the machine until the filled bottle emerges ready for packing in cases, no hands touch the bottles or the mixture. This machine has a capacity of twenty-four bottles a minute, and its smoothly functioning operation is something worthwhile seeing. All interior lighting is by the latest type of fleurescent fixtures.

______________________________________________

This is one of the fleet of five similar trucks that are distributing Spur to retail dealers. Standing at the machine is Charles F. Nelson, owner of the bottling plant, with a portion of the new building that houses the industry in the background. Besides these trucks all employees at the bottling plant, and those making deliveries, wear special uniforms.

_______________________________________________________

Article and photos from Newspapers.com.

Corrections and additional information should be added as comments to this post.