Short Mountain Colliery: Timeline 1920-1929

1920:

January 29th, the new washery began to operate.

Purchased 10” x 18” conveyor line for washery to reclaim slush bank south of washery. The line was never fully erected.

Purchased Cadillac Touring car.

Fire inside of lamp house, Lykens Valley side.

Purcahsed electric locomotive for Bear Gap Tunnel for service between No. 10 Slope and engine plane.

During peak of high water, 5,725 gallons per minute were delivered to the surface.

No. 9 Rock Slope extended to No. 9 Level.

No. 10 Rock Slope extended to No. 2 Level.

Strike of 19 days, but the washery continued work.

1921:

Washery boilers condemned and steam furnished by colliery.

Division Power Plant, pulverizing coal plant and high tension lines all completed. Work was done by H. C. Felver.

April 21st, started preparation for handling and storage of slush above power plant and breaker pump.

June 18th, slush pumped to power plant. The first boiler fired August 8th. The new boiler house shut down on September 20th. First electricity was delivered to Williamstown on October 15th. The Bull boiler house was shuttered on December 29th.

October 21st, started preparation for handling and pumping of slush from washery.

Purchased electric fan for No. 10 Rock Slope and placed it near the top of the Slope.

Purchased an electric locomotive for the No. 3 Level.

Sinking No. 10 Rock Slope.

Suspension: 29 days and a 1 day strike.

1922:

July 17th, started to dismantle the Allis-Chalmers Triturator in pulverizing plant. Preparing it for its return to Milwaukee. It shipped on August 17th.

Extensively repairing spray pond and baffle.

Placed duplicating dust conveyor system in power plant.

December, purchased an Oakland Roadster.

February 1st, fire at the pulverizing mill.

May, purchased an electric locomotive for the No. 4 Level.

Strike from April 1st to September 10th.

Missed a total of 142 days.

1923:

Work to remove ashes and mine refuse from the culm bank began in November. The contract for the work was given to Rhoads Construction Company.

Purchased Fuller Mills for pulverizing fuel plant.

Purchased motor generator set for power plant.

Placed one 20 ton motor truck scales at retail yard.

Extensive renewals and changes made on breaker tanks and troughs.

January 22nd, the breaker dumped 955 cars.

No. 10 Rock Slope completed to No. 3 Level.

November 5th, the washery was suspended for rest of year.

2 strikes lasting for more than 50 days.

1924:

Purchased one 3 ton white motor truck.

Completed tine line with East Penn Electric Company, amassing 22,000 volts.

Purchased first Reo Speed Wagon.

Purchased two No. 1 buckwheat jigs.

Purchased boiler feed pump for the power plant.

Renewed water trough from Bear Gap Tunnel to breaker.

April 23rd, the last car was hoisted from the No. 1 Level, No. 1 Shaft.

Purchased one 8 ton, 250 volt electric locomotive for the No. 4 Level.

1925:

Purchased spray pump for spray pond.

Placed flood lights on top of power plant.

October, rebladed the No. 2 turbine.

February, June and September spent extensively repairing the No. 1 turbine.

Began to rebuild the Reservoir and Dam in July and finished in October.

Placed brake bands on No. 1 Shaft, South Engine in April.

Started to repair No. 1 Shaft Engines in September and finished in December.

Began repairs to the air compressor in November and finished in January 1926.

Hoisted the last car from No. 2 Level, No. 1 Shaft on January 12th.

Placed electric pump on No. 3 Level, No. 10 Rock Slope.

Purchased cement gun.

January 28 – September 1: Washery work only. Suspension and strike.

Strike: 103 days

1926:

February 18 – Colliery resumed operation.

April 26- Cement gun was first used at No. 2 Shaft at Williamstown.

Purchased material for ash testing device on May 24.

June 1- Purchased one 8 ton electric locomotive for the No. 5 level, No. 1 Shaft.

July 14- No. 9 Slope closed for 4 days, pulling bar broke and cars went back.

July 21- Finished removing refuse from top of culm bank, top of Polish Row, which started in November 1923.

August 2- Began excavating for addition to bath house, west end of Big Lick Mountain.

August 4- Rhoads Construction Company skipping bank to make place for road from breaker to retail yard.

August 7- Placed 10” meter on water line in Glen.

August 25- Erecting new No. 1 buckwheat jig.

September 3- Approved order to Ingersoll Rand XPV-3 Plate Valve air compressor, to be placed in old brick power plant building, near No. 1 Shaft.

September 16- Finished concrete wall behind power plant and pulverizing mill.

September 17- Building ticket and lamp house, No. 1 Shaft.

October 22- Union fee raid to $50.00.

November 16- Rained 5.29 inches, No. 10 Slope idle on November 19th due to high water.

November 22- Washery employees refuse to work 10 hour shift.

August 19- Air compressor broken, repaired December 1.

Spray pond tunnel leaking at Division power plant; bought power from Monday, December 6 until Friday, December 10.

December 16- Began to entirely replace the slate bank conveyor line at the washery.

Began driving No. 12 Slope tunnel, preparing to sink No. 12 Slope from No. 5 Level, East No. 1 Shaft, July.

Placed new column line, 1480 feet, on No. 10 Slope to take care of new electrical pump at No. 3 Level.

Finished electric pump No. 9 Level, No. 9 Slope.

Washery- strike, 41 days; worked 97 days. The rest were idle due to suspension.

Total colliery strike of 40 days.

1927:

February 15- Finished building slate conveyor across the road from Short Mountain washery.

February 16- Rebuilding broken coal jigs in breaker.

February 24- Purchased five McCaa Rescue Apparatus.

February 25- Finished erecting new air compressor in cement block building near No. 1 Shaft.

April 30- Red Shale Gangway, West No. 3 Level, finished.

May 6- Installing engine on top of plane at end of West Red Shale Gangway No. 3 Level

May 13- Installed fan No. 4 Level East.

May 31- Purchasing material for experimental separator.

June 25- Making retaining wall along No. 1 Drift.

July 14- Moved contents of lamp house to top of No. 1 Shaft and into a new building

July 22- Rained 8.06 inches from 4 p.m. to 4 a.m.

August 23- Power plant tied to Pennsylvania Power and Light Company of Pine Grove. Testing phase.

October 3- Four cars jumped the track, closing No. 9 Slope until the 7th of October.

October 7- Fire discovered at 6:30 a.m., No. 4 Level, East Big Vein No. 10 Section. Declared out on March 3, 1928.

October 12- Explosion on No. 4 Level East, about 8:50 a.m. at No. 3 cross-cut. Mr. John Betz, division engineer, burned and injured. Died en route to Harrisburg Hospital.

November 1- Mr. D. V. Randall appointed General Superintendent.

November 3- Began to replace the No. 1 dryer shell in power plant.

Colliery worked 229 days; suspended 34 days; strike 3 days.

1928:

January 21- Surveying to place fresh water pump near Rattling Creek south of Lykens Mercantile Company near company ice dam.

March 2- Diamond drilling began today on Pat Martin East No. 3 Level, No. 10 Slope.

March 6- Began to excavate for foundation to place 9000 kilowatt turbine at Division power plant.

March 13- Second dryer shell for power plant arrived on this date.

April 28- 18” of snow in Bear Valley, the high tension line going to Williamstown was blown down by sleet and snowstorm.

May 6- Breakdown in the No. 2 Level near pumps, breaking pipes and blocking ditch. Colliery was idle 7th and 8th. No. 9 Level did not work until June 11, 1928.

May 18- New Meteor ambulance arrived from Pique, Ohio.

June 3- First set of relief timber put in No. 1 Shaft.

July 17- Poured concrete for pump house near Rattling Creek.

August 13- Mr. R. A. Quin, Vice President. Mr. D. V. Randall, General Manager.

August 20- Finished erecting two new, red, round, fresh water tanks above power plant.

August 31- Placed casing for water company pump house, top of Polish Row.

September 14- Began to clean out Bear Creek, at the Wiconisco Creek with a steam shovel.

October 5- Turned water into reservoir for new pumping plant along the Rattling Creek.

October 7- Fire discovered at top of pumpway from No. 7 Level to No. 5 Level. Sealed and slushed finishing November 21; Colliery working November 22, 1928.

November 2- Placing electric pump at No. 7 Level to replace one destroyed by fire.

November 23- Began to pump fresh water from new reservoir near the Rattling Creek to power plant tanks.

December 6- Put new cylinder on south shaft engine.

December 28- Placed safety posts along hill going to colliery.

December 29- Started water company electric fresh water pump, top of Polish Row, closing down fresh water pumps at Short Mountain washery.

Washery worked 298 days; colliery worked 205 days; colliery suspended for 32 days.

1929:

January 13- Tunnel being driven from Whites Vein to Red Shale No. 5 Level around fire zone, struck Red Shale today.

January 15- Mr. V. V. Secor, Station Engineer, and Mr. Thomas McGretty , Assistant Station Engineer, resigned.

January 16- Mr. Well Chaundy, Station Engineer, and Mr. George Wilt, Boiler Room Foreman.

February 19- Closed down fresh water pumping plant near retail coal yard.

March 31- Fire zone in pumpway from No. 7 to No. 4 Levels closing, after pumping 2495 mine cars of slush.

April 16: Timber bank given contract to Mr. Charles Hoffman & Fred Hoffman.

April 24- Began foundation for new coal tester house, foot of hill, north of retail yard.

April 28- Installed car stops at top of No. 1 Shaft.

May 6- Tearing down the last red company house, north of Coaldale.

June 4- Installed electric pump, No. 8 Level, No. 1 Shaft.

June 10- Installed tugger at No. 5 Level, No. 1 Shaft.

June 13- Driving tunnel, No. 5 Level, No.1 Shaft for Barney Hoist engine house.

June 25- Began placing 12’ steam line between power plant and air compressor.

July 25- Began to erect electrical engine at tunnel plane.

July 30- Lykens Water Company installed chlorinator at Lykens Reservoir at noon.

August 14- Pennsylvania Power and Light Company cutting line down Big Lick Mountain, west of Williamstown Colliery to run light line to Lykens Valley.

August 30- Began to install car stops at breaker.

September 3- Began to repaint high tension line towers.

September 6- Purchased new Chevrolet sedan.

September 12- Began installing No. 3 buckwheat jigs at breaker.

September 21- Began placing red tickets with the coal shipments to distinguish our coal from others.

October 1- Began bringing up five cars a run on No. 9 Slope.

October 5- Mr. E. A. Van Horn resigned as Superintendent of this division, here since October 16, 1919.

October 15- Began driving raise from No. 3 Level, No. 10 Slope for No. 11 Slope.

November 1- Mr. W. B. Geise, Superintendent of this division.

Washery worked 129 days; colliery worked 164 days; colliery suspension 133 days

_____________________________

Posted by Jake Wynn on PAHistorian Blog, 14 May 2013.

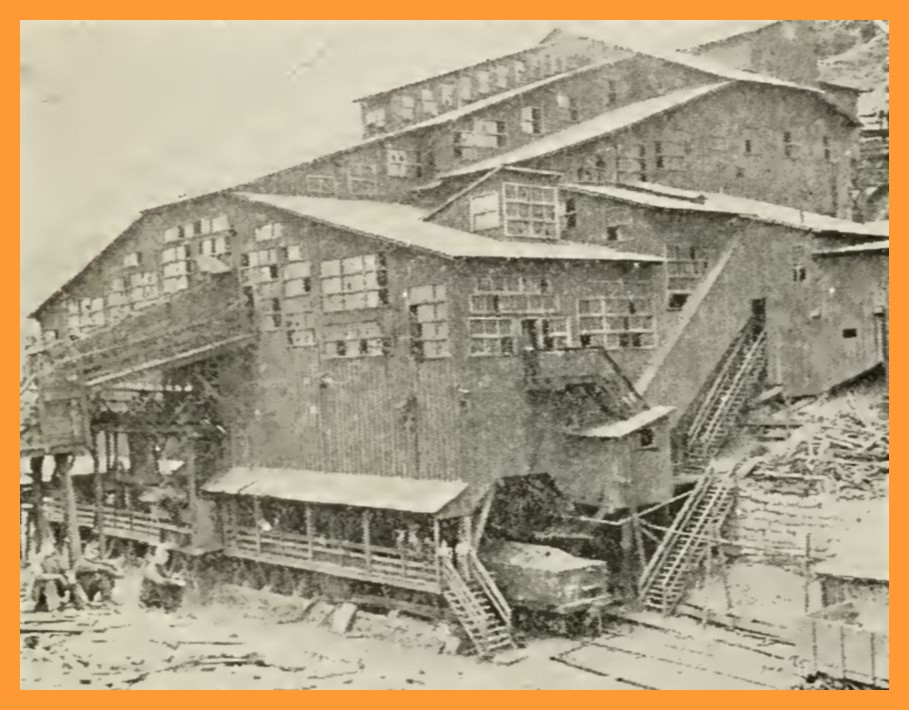

The picture, “Lykens Valley Breaker: Loading Cars,” is from Bicentennial History of the Lykens-Williams Valley.